Novinium: Unexpected Reuse and Resource Reduction Beyond Where the Eye Can See

Novinium extends underground power cable life by 20-40 years and creates quality jobs

The U.S. Environmental Protection Agency (EPA) describes resource use reduction and reuse as the most “most effective ways [to] save natural resources, protect the environment and save money.” In fact, the EPA states:

The most effective way to reduce waste is to not create it in the first place. Making a new product requires a lot of materials and energy – raw materials must be extracted from the earth, and the product must be fabricated then transported to wherever it will be sold.

Many consumers and businesses think about reuse and extending the useful life of items commonly seen in daily life. But there are opportunities for materials reuse well beyond these commonplace household and business goods.

SJF portfolio company Novinium specializes in extending the life of something unexpected, something we use every day but don’t often see—underground power cables.

Problem

In the United States, over five billion feet of underground electrical power cables were laid since the 1960’s. These cables have a useful life of approximately 20-40 years, meaning a significant portion of the cable laid in the 1960s-1990s is becoming worn down or failing. Underground cables eventually endure water damage, resulting in power failures and other complications. Utilities have traditionally had little choice in what to do when this happens and needed to purchase new cable, dig up the old lines and install new cables underground as replacements.

Novinium’s Solution

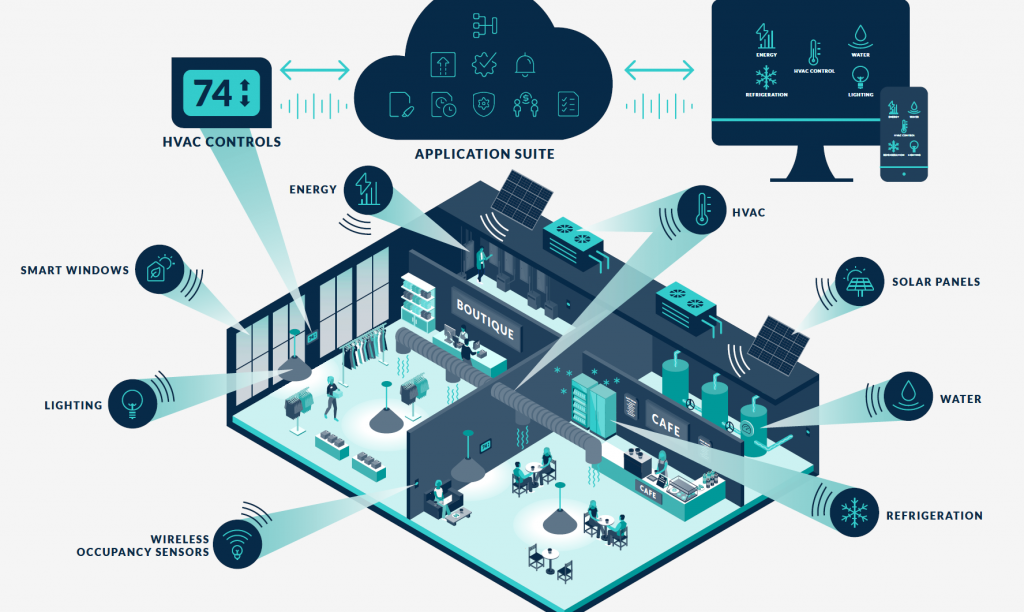

Novinium now offers a radical alternative to this problem. Its proprietary cable rejuvenation injection process can be administered in situ, i.e. without digging up all the old cable and removing it. The result repairs and extends the useful life of underground power cable by 20-40 years—doubling its lifetime. That length of useful life extension is rarely seen in other recycling and reuse industries.

Environmental Impact

There is a significant environmental resource savings as well as transportation and other cost savings created by Novinium’s technology and process. Specifically, for every meter of cable injected:

- 16 grams of silicon fluid are used;

- 195 grams of aluminum are saved;

- 484 grams of copper are saved;

- 963 grams of plastic are saved; and

- Diesel fuel (1.09 gal/meter of cable) is eliminated for: transporting the cable, factory to site; taking bigger construction equipment to the site; and drilling, trenching, or using a backhoe.

Since its founding, Novinium has enabled over 150 million feet of power cable for reuse for an additional 20-40 years. Reuse of these existing power cables has saved almost 10,000 tons of aluminum, 24,000 tons of copper, 48,000 tons of plastic, and 50 million gallons of diesel fuel.

Novinium also provides a greater impact on improving the reliability of the aging U.S. grid and reducing power outages. Its process saves up to 70 percent versus the cost of cable replacement, allowing utilities to address a significantly larger portion of high-risk cable in danger of failure. Power outages have increased 285 percent since 1984, and the U.S. ranks last among the top nine Western industrialized nations in the average length of outages, which the federal U.S. Energy Information Administration says cost businesses as much as $150 billion a year.

Case Study: St. Charles Municipal Electric Utility

One example of Novinium’s work and impact can be found with the St. Charles Municipal Electric Utility, located outside of Chicago, IL and serving more than 15,000 residential and commercial customers. In 2009, Novinium began assessing and rehabilitating the highest prioritized subdivisions identified by St. Charles. Each segment was tested and categorized for either rejuvenation or replacement based on Novinium’s injection criteria. Between 2009 and 2012, Novinium and St. Charles rejuvenated 169,829 feet (77 percent) and replaced 50,127 feet for a total of 219,956 feet.

An average of eight years of failure data exists pre- and five years post-rehabilitation. Prior to rehabilitation St. Charles recorded a total of 66 failures. Since rehabilitation, this cable population has experienced only two failures. The cost to replace all of the addressed cable would have been $6.6 million. Using a comprehensive approach of rejuvenation and replacement, St. Charles spent just $2.3 million. This saved $4.3 million, or 66 percent, and most importantly, achieved reliability results comparable to newly installed cable. The injected cable has been restored to as-new condition and is covered by a 40-year warranty.

Community and Workforce Impact

In addition to its environmental benefits, Novinium has created a positive impact on its community and workforce. Its headquarters is located in a low-income economic hot zone where its tract income level is only 40.1% of median area income. The company has created 275 quality jobs, of which 186 are hourly workers with an average wage of $31.28 per hour. Employee benefits include medical, dental, vision, disability and life insurance; paid time off; paid holidays; and a 401(k) plan with company matching. Novinium was named as one of Seattle’s 2013 Best Places to Work.

© Copyright 2024 SJF Ventures

© Copyright 2024 SJF Ventures