Optoro Creates Environmental Impact Model

New model demonstrates how Optoro customers can achieve reduction in CO2 emissions and waste

Company Background

Optoro is revolutionizing the reverse logistics business in a way that provides meaningful financial and environmental returns. Optoro utilizes its technology platform to optimize the processing, disposition, and selling of returned and excess retail consumer goods. Optoro’s cloud-based SaaS reverse logistics technology (“OptiTurn”) optimizes a retailer’s recovery rates and channel allocation, while also saving fuel costs and reducing the total distance items are shipped.

The end-to-end reverse logistics process is long and complex and presents many challenges to retailers. There is an uncertainty of the supply or timing of returned goods. Retailers are often unable to maximize recovery rates for returned items without creating channel conflict or compromising their brand. They also struggle with maintaining transparency of their reverse logistics supply chain and face coordination challenges among the many different parties in the process.

Optoro’s addressable retail returned goods and excess inventory market is approximately $500 billion. Of the annual U.S. retail sales of approximately $3.1 trillion, $266 billion (8.6%) is returned to retailers and $223 billion (7.2%) is excess inventory. Optoro’s value-add is highlighted within the consumer electronics market. There are $23 billion returns of the $208 billion in consumer electronics retail sales. Of these returns, only approximately 5% ($1.2 billion) are defective, while the other 95% ($21.8 billion) is new or like new. Without the OptiTurn solution, many of these like-new items are disposed of because there often aren’t easy avenues through which to sell these items and many items become damaged in transit.

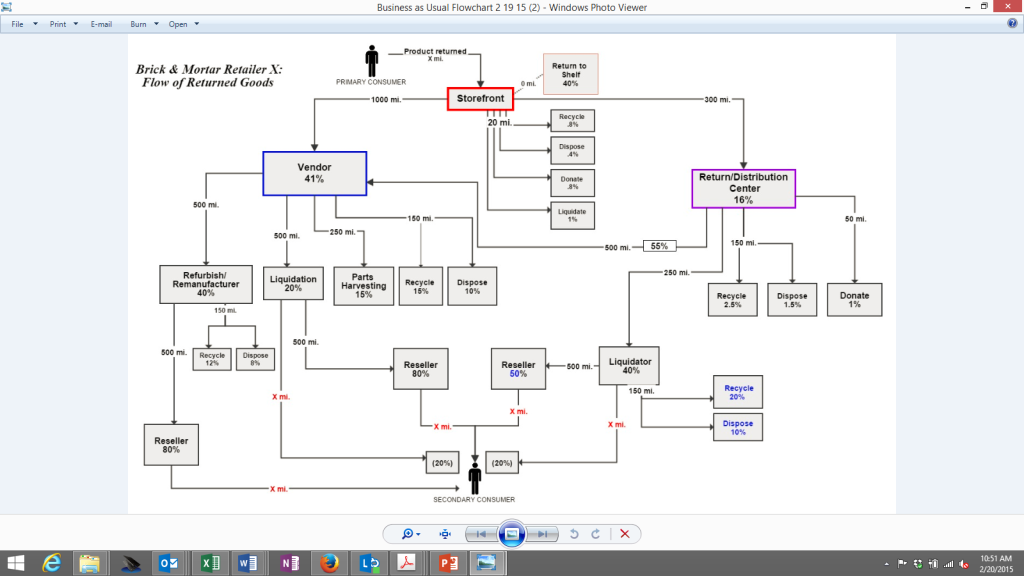

Example of how returns are traditionally processed:

Despite these challenges, retailers are increasingly viewing their reverse logistics capabilities as a potential strategic competitive advantage. Optoro helps retailers develop this advantage by offering a solution that increases recovery rates, increases reverse logistics supply chain transparency, and improves coordination among participants. Currently Optoro’s Optiturn proprietary software is used to help retailers sell products across channels including eBay, Sears, Amazon.com, buy.com, Best Buy, Google, Yahoo!, and Rakuten. Additionally, retailers can sell through Optoro’s own Blinq marketplace, allowing them to avoid channel conflict.

Throughout its product offering, Optoro provides workflow analysis, inventory management, and processing capabilities to retailers’ facilities located anywhere in the country. In addition to the economic value created, Optoro’s solution generates environmental value by reducing excess waste and CO2 pollution created in the traditional reverse logistics process.

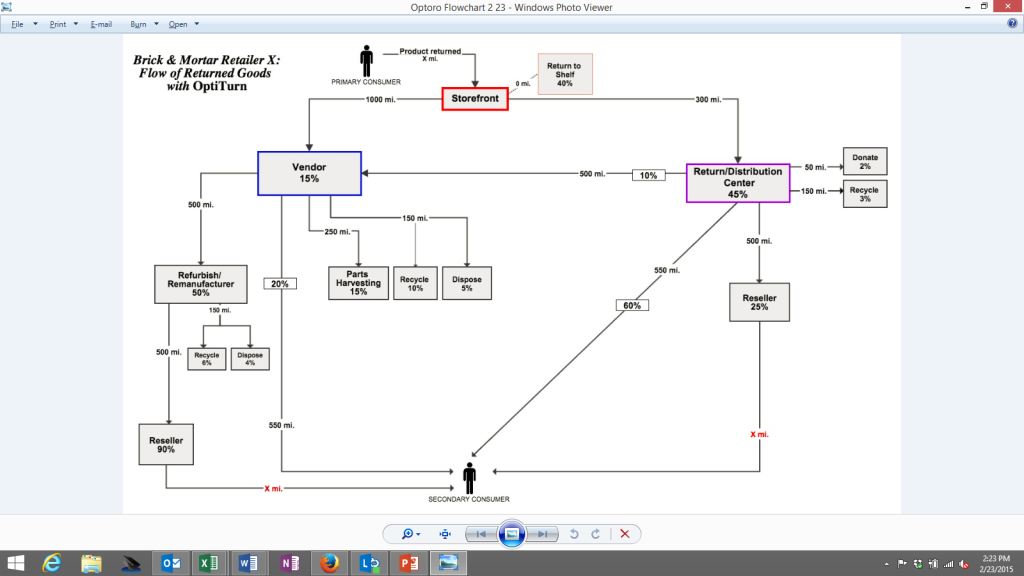

How OptiTurn can change the flow of goods:

Environmental Impact Model Project

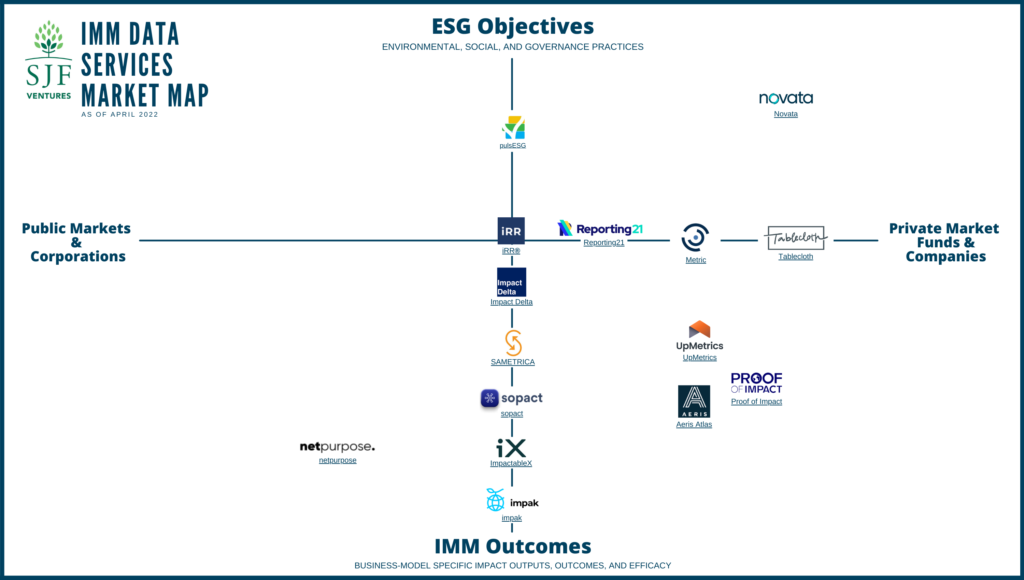

In 2015 Optoro set out to develop a model to use to help calculate the carbon and waste savings its products generate for retail store customers. A team from the University of Virginia Darden School of Business, along with help from Optoro investor SJF Ventures and the environment experts at Environmental Capital Group, worked with the company to generate a model that can calculate a retailer’s carbon and waste savings after implementing Optoro’s reverse logistics OptiTurn product.

In creating the environmental impact model, the Optoro team focused on the following primary impacts:

Carbon emission savings from reduced transportation

Consumer goods are typically first returned to a store, which then sends them to a distribution center. This distribution center may send the returned goods to a vendor. The vendor then refurbishes a portion of the product and then sends a portion to a liquidator. The refurbisher will send a portion to reseller and recycle another portion. Trucks are carrying these items each leg of the journey, often not at a full load. Each of these truck trips puts unnecessary carbon dioxide (CO2) into the atmosphere. Optoro’s products significantly simplify and shorten consumer goods reverse logistics travel distances and therefore the company chose this impact as its primary customer carbon savings method in the model.

Waste savings from Optoro’s more efficient reverse logistics

In addition to the carbon impact of the many legs of the journey, Optoro’s solution helps retailers send fewer returned goods to the landfill. Fewer transit trips also mean that fewer goods are damaged during the process and thus fewer items are disposed of during the reverse supply chain. By reducing the reverse logistics travel, Optoro’s solution reduces the amount of goods disposed before reaching a secondary consumer because of travel-related damage or low value.

In addition to carbon savings from reduced transportation and waste savings from a more transparent, simplified reverse logistics workflow, Optoro’s products generate other positive environmental impacts. These include carbon and waste savings from increasing the consumption of pre-owned goods and therefore potentially reducing the need for new manufacturing and raw materials to meet consumer demand. However, these related environmental impacts required more advanced assumptions that the company did not feel it could confidently make today and were thus not included in the current model.

![Lanham, MD -- 12/09/2014 -- Paul Alexander moves boxes of equipment into the quality control area for testing and inspection at Optoro's warehouse Tuesday, Dec 9, 2014. [ / _KF23984.JPG] (Karl Merton Ferron / Baltimore Sun)](https://sjfventures.com/wp-content/uploads/2015/11/warehouse-1024x637.jpg)

Lanham, MD — 12/09/2014 — Paul Alexander moves boxes of equipment into the quality control area for testing and inspection at Optoro’s warehouse Tuesday, Dec 9, 2014. [ / _KF23984.JPG] (Karl Merton Ferron / Baltimore Sun)

Results

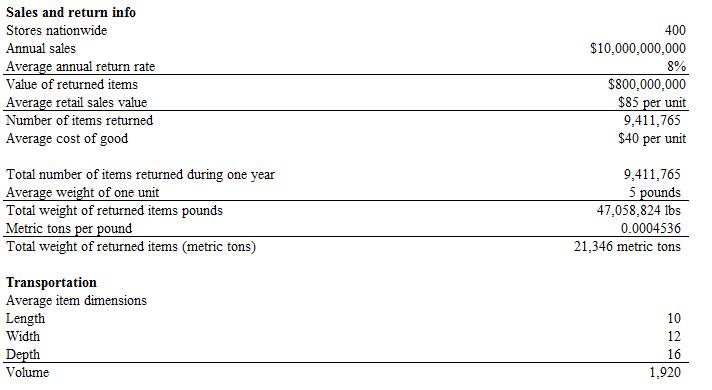

Optoro’s impact model takes inputs as to the amount of returned goods, average weight and volume of returned units, distance to distribution centers and other related liquidators and refurbishers, mode of transportation, and average percentages of returned goods sent to landfill, recycled, remanufactured, sold to third parties, etc.

The model reports what a retailer with specific annual sales, returns and other proprietary characteristics, would likely generate in terms of carbon dioxide (metric tons of CO2) and waste (units and weight by tons sent to landfill or incinerated) output from its own reverse logistics model and then after implementing Optoro’s solution. The model compares the “with Optoro” and “without Optoro” scenarios to calculate the carbon and waste savings generated by Optoro’s product given a set of input assumptions.

The model will serve as a tool to help the Optoro team quantify and communicate its environmental impact to both current and potential retail customers. In addition to carbon and waste output metrics, the model can also compare total annual reverse logistics miles traveled, average miles traveled per returned unit and the related fuel savings offered by Optoro, which highlights the interrelated economic and environmental customer benefits.

The example below highlights Optoro’s carbon, waste and fuel savings impact for a hypothetical home goods retail customer with $10B annual sales.

Example of savings for single home goods retailer using Optoro’s model compared to traditional model

Assumptions

Results Summary

Total CO2 emissions saved by implementing OptiTurn: 27% reduction in CO2 (5,042 metric tons of CO2)

Equivalent of cars removed from the road: 1,031 cars

Equivalent to planting: 129,283 trees

Items saved from direct trip to landfill via Optoro: 824,574 units

Tonnage diverted from landfills via Optoro: 3,740 metric tons

“The project got us thinking through some of the challenges as well as the opportunities that accompany this kind of analysis,” said co-founder and president Adam Vitarello. “[The] next step is to use this hypothetical model to quantify emissions and waste abatement for one of our major retail clients.”

Vitarello concluded saying Optoro was “thrilled to work with [the Darden] team to begin to quantify the environment benefits of our solution,” and the team “did a great job helping us build out the initial model and put us on a path to demonstrating these impacts to our clients.”

© Copyright 2024 SJF Ventures

© Copyright 2024 SJF Ventures